Circularity

Circularity is one of the main concepts to reduce the impact of human consumption on the environment. In fact, circularity is one of the fundamental principles of biological life and as well by no means new to human society. For example the parish churches of Atcham, Wroxeter, and Upton Magna are largely built of stone taken from the buildings of Viroconium Cornoviorum.[1] In fact the practice of reusing building material was so common that it got its own term: Spolia, derived from Latin “spolium” for spoils.

Several approaches to circularity exist with different reduction of energy and raw material demand. Setting up a hierarchy the following levels of circularity have been identified:

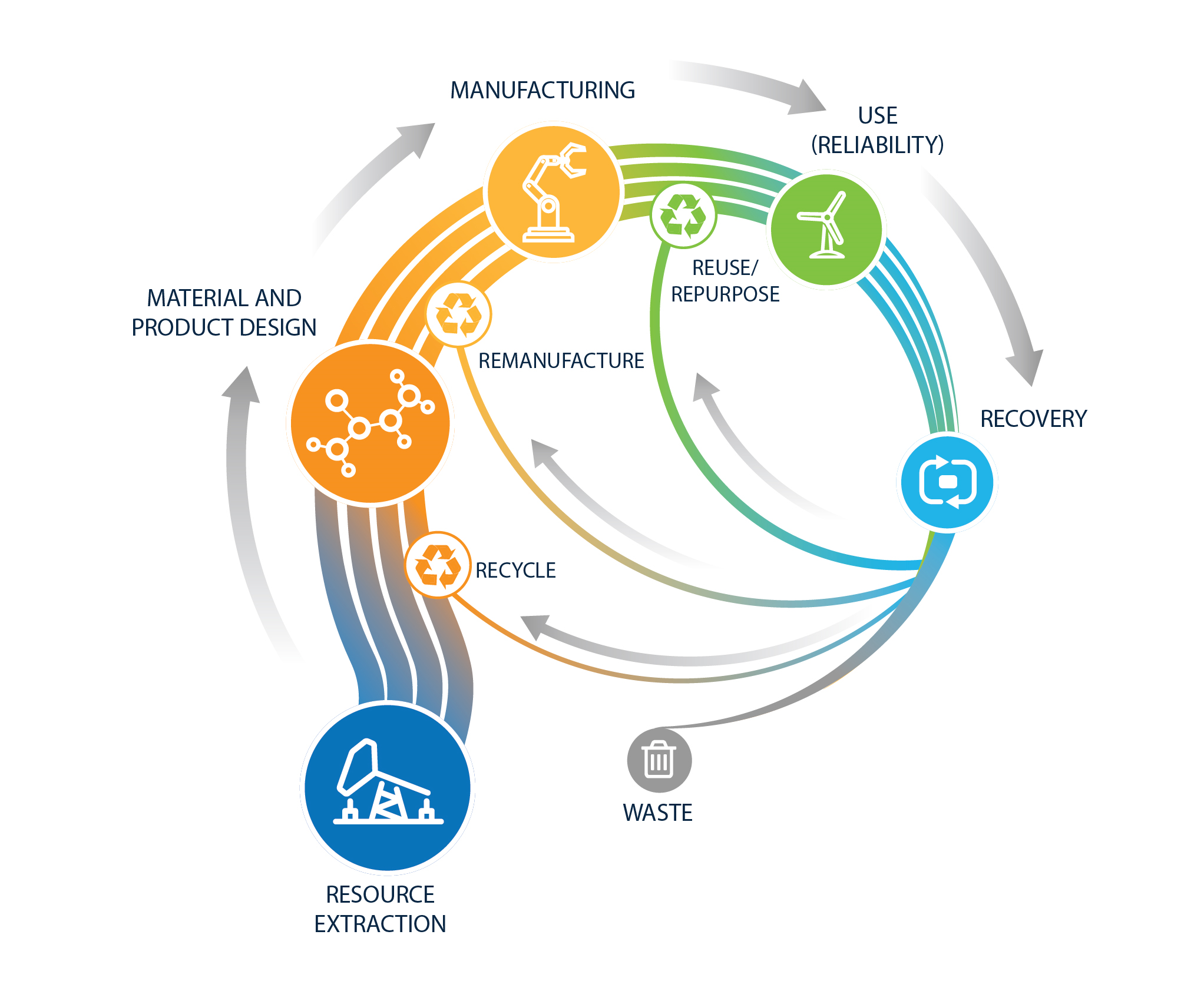

Strictly speaking the two highest levels do not concern circularity but non-circular aspects. However, they are crucial to facility a circular material approach. The general setup of circularity in material streams from raw material extraction to waste disposal is depicted in the following graphics:

Each step from raw material sourcing to end-of-life treatment is crucial for circularity. Raw materials can for example originate from geological extraction, renewable sources or recycling. Material and product design and development influence subsequent manufacturing, use and durability, possibility of repair, reuse, remanufacture or recycling.

Recycling

Although low in priority, recycling is one of the key components on the way to a more sustainable industrial setup, especially for single-use items like certain packaging types or medical devices. Furthermore, the chemical industry is mainly about carbon-based molecules and the reliance on fossil carbon sources is not sustainable. Fossil carbon sources as supply for the chemical value chains are considered a problem not only in view of climate change but also of dwindling natural resources.

Be that as it may, different classes of recycling itself exist depending on the stage at which the material is reintroduced into the production process. In general following classes with increasing production steps to the final material are widely recognized:

- Mechanical Recycling: The waste is sorted into fractions according to material types. Each fraction is then processed e.g., shredded and pelletized to be used as input for new production. Mechanical recycling is limited to fusible materials like thermoplastic polymers or metals.

- Physical Recycling: Physical recycling of polymers comprises various processes for separating the different components from plastic parts to isolate polymers of nearly virgin quality suitable for compounding new materials. Current processes are at research or pilot-plant stage.

- Chemical Recycling: In chemical recycling polymer molecules are cleaved into smaller units. Depending on the type of cleavage different types of chemical recycling for polymers are:

- Depolymerization: The polymer is transformed into its original monomers or a precursor of these monomers. A common method is hydrolysis (solvolysis) of polyesters to acids and alcohols. This type of chemical recycling is limited to mono-material polymers with defined cleavage sites like ester moieties while in polyolefins statistical cleavage of carbon-carbon bonds leads to complex mixtures of smaller molecules. Depending on conditions depolymerization can lead to oligomers of varying length or in case of complete depolymerization back to monomer units.

- Pyrolysis/Gasification: If depolymerization is not feasible, pyrolysis or gasification is a means of transforming waste materials into small molecular entities as raw materials for new production processes. However, the processes lead to a mixture of small molecules, require a lot of energy and process steps from the material output to new products.

Chemical recycling of metals is very common, especially for high-value materials like precious metals. Chemical recycling in this context means transforming the metals or their alloys into a soluble form, separating and purifying the different metal types and reintroducing them into the normal production process.

While mechanical recycling is already well established (with small to medium-sized facilities geographically widely distributed) the other classes are far less common and did partly no exceed pilot plant stage. An overview of mechanical recycling rates of plastic packaging in Europe is given in the following figure.

Another aspect to consider regarding recycling for usage in the same application is product safety. Therefore, the European Union has setup a regulatory framework applicable for the recycling of food contact materials:

To facilitate recycling several approaches exist, some of which directly relate to innovation in the chemical industry:

- Design for Recycling:

- Mechanical: Ensure possibility of disassembly into parts made from different materials

- Material: Use mono-materials instead of composites and laminates

- Polymer: Optimize polymer for repeated melting, reduce degradation

- Avoid materials with no available recycling stream or technology

Footnotes

- See https://en.wikipedia.org/wiki/Spolia and Barker, A. Philip (1977). Techniques of Archaeological Excavation. Routledge. p. 11.

- Cramer, J. (2017). The Raw Materials Transition in the Amsterdam Metropolitan Area: Added Value for the Economy, Well-Being, and the Environment. Environment: Science and Policy for Sustainable Development, 59, 14–21. https://doi.org/10.1080/00139157.2017.1301167.

- S. Ovaitt, H. Mirletz, M. Mendez Ribo (2023). NREL/PV_ICE: v0.3.2 Release. Zenodo. https://doi.org/10.5281/zenodo.7651576.

- Crippa, M., De Wilde, B., Koopmans, R., Leyssens, J., Linder, M., Muncke, J., Ritschkoff, A-C., Van Doorsselaer, K., Velis, C., & Wagner, M. (2019). A circular economy for plastics: Insights from research and innovation to inform policy and funding decisions. European Commission EC. https://doi.org/10.2777/269031.